Biotech company -UAB LT BIOTECH

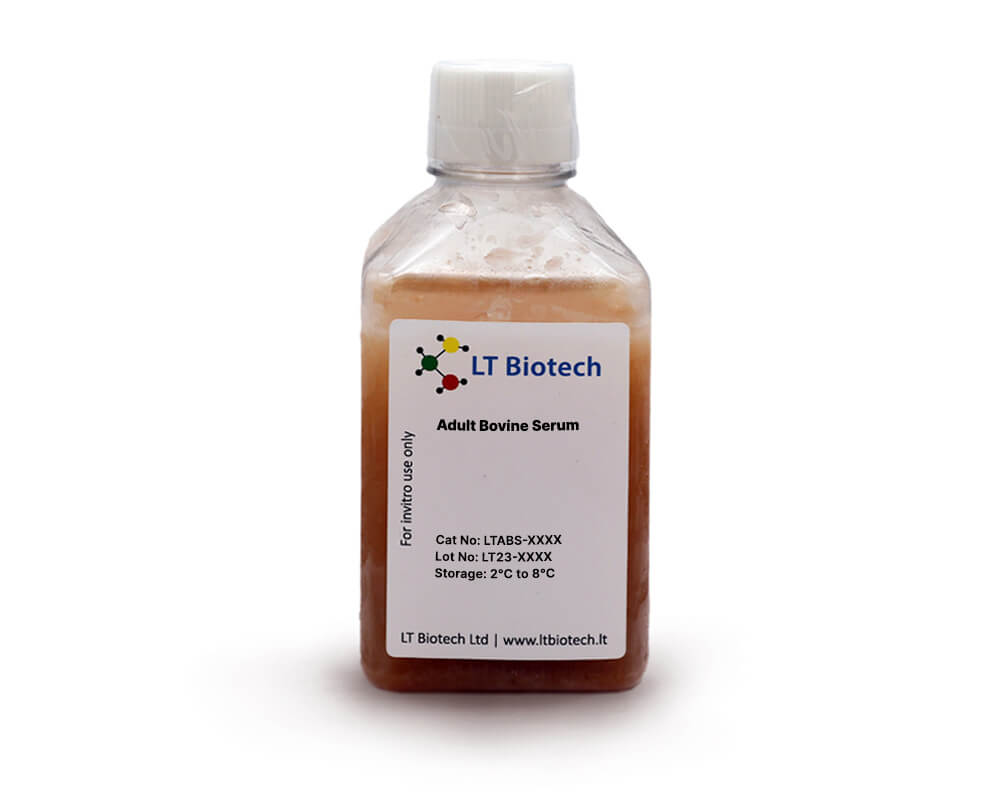

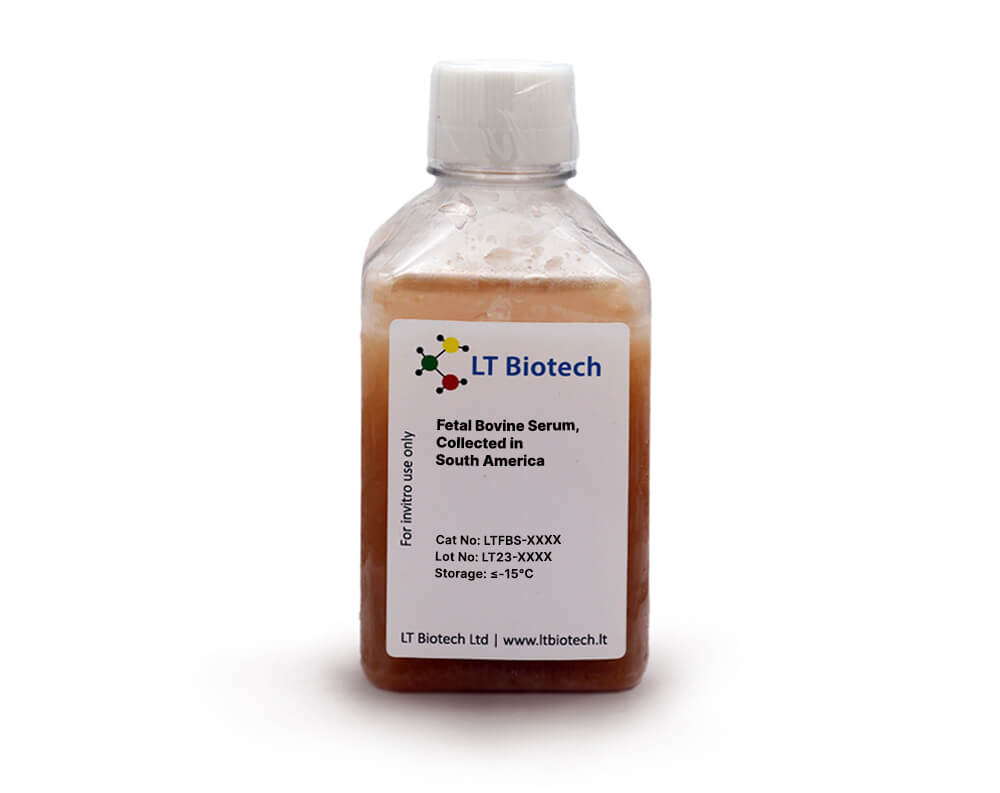

developing sensitive systems for human and veterinarian diagnostics, sera and media for cell cultivation.

LVPA/LBSA Projects

Research and development

• Spectroscopy

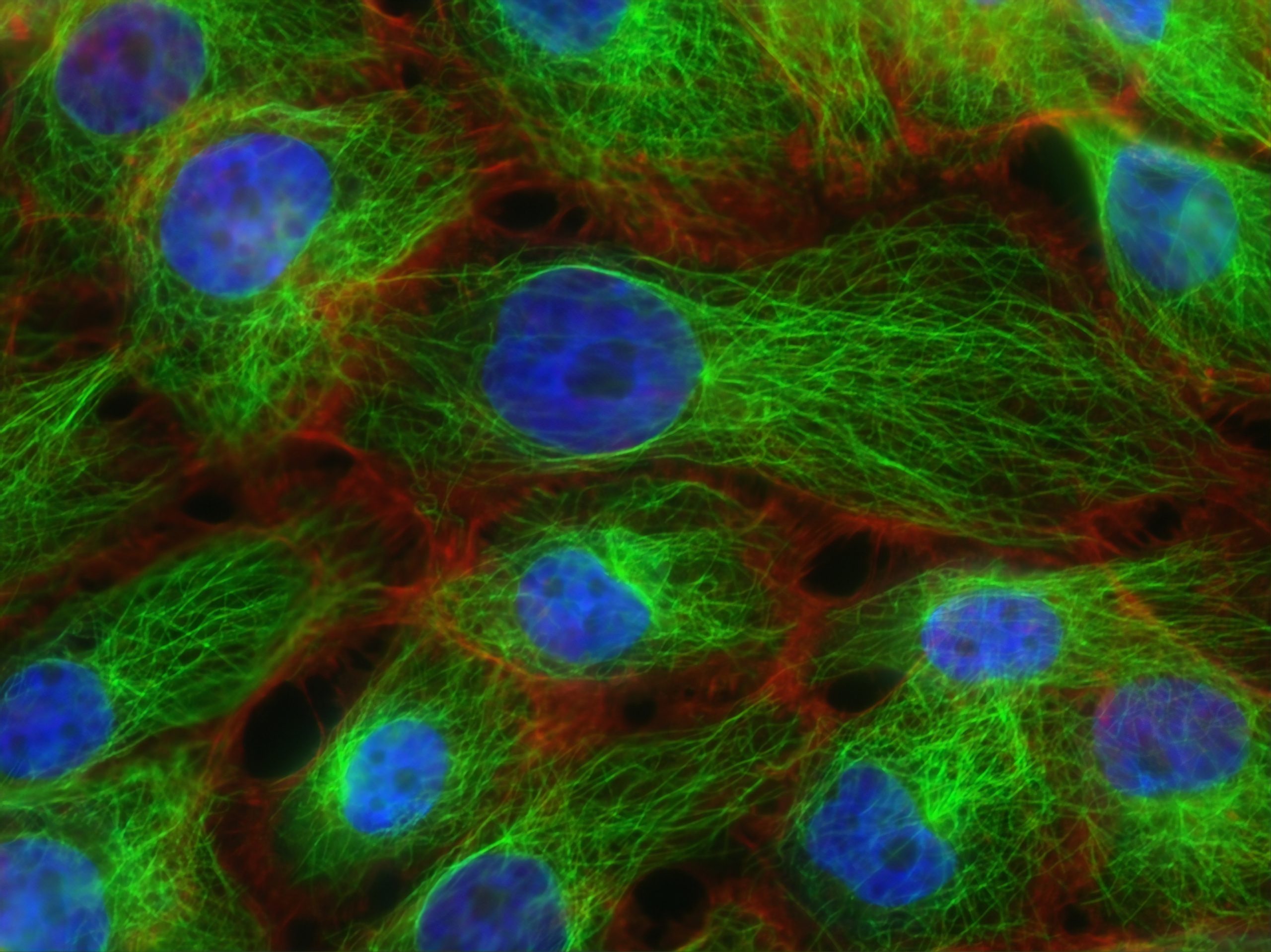

• In vitro diagnostics development

• Bioprocess techniques

• Bio affine systems

• Customized media development

Vision

Our goal is to expand our product portfolio to encompass the entire range of academic and industrial needs in the fields of media and diagnostics.