Products

Glassware (bottles, ampoules, vials)

Assortment of glass vials and ampoules

STANDARD AMPOULES:

- Form B

- Form C

- Form D

Ampoules for with individual parameters:

- Form E (Marzocchi)

- Double neck

Volume: 1 to 30 ml

Productive capacity: Up to 2.5 million ampoules per day

LINE EQUIPMENT:

- Automatic loading of glass tubes

- Up to 3 code rings

- Colored Break Point ring

- Break Point Ampoules (OPC)

- Break Point notching ring

- Automatic print

- Dimensional check chamber

- Print test chamber

STANDARD VIALS:

- ISO 13 and 20

- GL 14, 18, 22

- FEA 13, 15, 18

- SCREW NECK (PFP, EUR)

Custom vials:

- Double fixation

- Dosing device

- Internal annular groove on the bottle neck

Volume: 1 to 60 ml

Productive capacity: Up to 300,000 pcs. in a day

LINE EQUIPMENT:

- Automatic loading of glass tubes

- Dimensional check chambers

- Visual inspection cameras

- Automatic print

- Clean room

- Automatic packaging system

- Equipment for interior coatings (ammonium sulfate, silicone)

LW7. STANDARD NON-PYROGENIC INNOVATIVE PACKAGING

VIALS LW7/LS5 | GIT (Glass In Touch)

- Mass production

- Flushing with water for injection (WFI), 83 °C

- Filtered air blow (20 p)

- Static oven (minimum 60 minutes at 150°C)

- Single bag packaging, ISO 5 (Easy Pack), fully recyclable

- Reducing waste after packaging

- Reducing laboratory testing

- No preservatives

- Conditions in accordance with the requirements of GMP rules

- Test for visible and invisible mechanical inclusions

- LAL test and microbiological purity test using water for injection (WFI)

LS5. STERILE APYROGENIC INNOVATIVE PACKAGING

We take over the work involved in washing and sterilizing primary packaging so that pharmaceutical companies and laboratories, even small ones, can focus on solving patient health problems.

LS5 guarantees 10-12 sterility, prevents ethylene oxide treatment of packaging and reduces up to -40% of the environmental impact of packaging (our packaging is 100% recyclable).

LS5 is a complete solution for product packaging:

- Affordable sterile and apyrogenic primary packaging at affordable prices

- Available, even in small quantities, with a wide range of elastomeric stoppers (always in LS5 configuration) and aluminum caps (both standard and combination Flip-Off type) included in the service

- The innovation can also be extended to customer-owned primary packaging

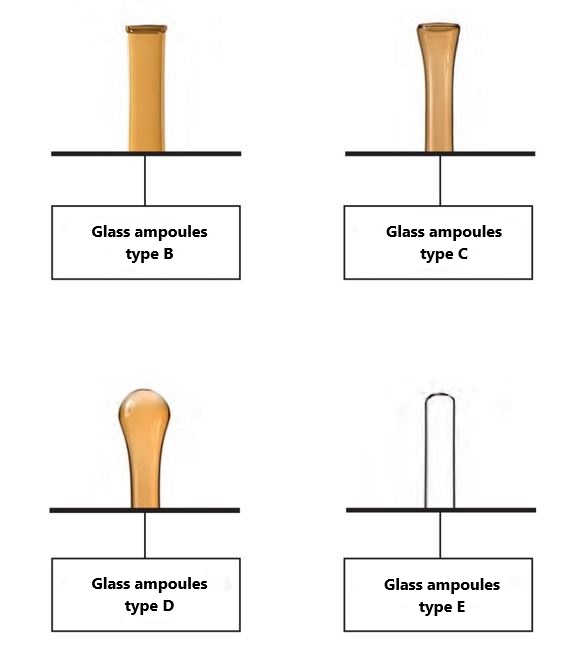

Glass ampoules

We offer four types of ampoules:

ISO 9187-1 glass ampoules type B

Hydrolytic class 1 glass, ø min. 10.75/max. 22.50, colored or notched break ring/code ring/ampoules with break point/printing/ammonium sulfate/silicone.

ISO 9187-1 glass ampoules type C

Hydrolytic class 1 glass, ø min. 10.75/max. 22.50, colored or notched break ring/code ring/break point ampoules/printing/ammonium sulfate/silicone.

ISO 9187-1 glass ampoules type D

Hydrolytic class 1 glass, ø min. 10.75/max. 22.50, colored or notched break ring/code ring/break point ampoules/printing/ammonium sulfate/silicone.

Glass ampoules type E

Hydrolytic class 1 glass, ø min. 10.75/max. 22.50, colored or notched break ring/code ring/break point ampoules/printing/ammonium sulfate/silicone.

Glass vials

Manufacturing according to individual parameters:

- Screen printing, 1 color

- Internal and external silicone treatment

- Internal treatment with ammonium sulfate

| SKU | DIN/ISO 8362 – 2R/3R/4R | DIN/ISO 8362 – 6R/8R | DIN/ISO 8362 – 10R/15R | DIN/ISO 8362 – 20R/25R/30R |

| Standard colors | Clear glass or dark glass | Clear glass or dark glass | Clear glass or dark glass | Clear glass or dark glass |

| Ø | 16 | 22 | 24 | 30 |

| H | 35, 40, 45 | 40, 45 | 45, 60 | 55, 65, 75 |

| ml | 2, 3, 4 | 6,8 | 10, 15 | 20, 25, 30 |